Becoming the Digital Craftsman

Experiments on Craftsmanship and Digital Fabrication

Digitale Medien MA

bei Prof. Dennis Paul Prof. Ralf Baecker

Pottery is an ancient craft that can be traced back up to 25000 BC. All known cultures used clay to make ceramic goods from it.

First, by laying clay coils on top of each other and spread them together, to join them and pull up the walls of ceramic vessels. The innovation of the spinning pottery wheel came about 4000 BC.

Today, the material has lost little of its significance, ceramics can be used in an even wider range of potential applications – from classic tableware to technically sophisticated products. Therefore the material is highly versatile, yet, at the same time limited in its fields of applications due to its physical properties. On one hand, it is very fragile, almost sensitive, for example in the form of porcelain and on the other hand extremely robust and durable, considering industrial ceramic coatings.

“3D printing ceramics has the potential to bring back the unique and individualized objects that artisans make. But, this time it is a machine who manufactures the final product […] and shows the potential of cutting edge technology while reminding us of the days of yore.” Van Herpt – 3D Printing Ceramics. Introducing elements of randomness

Clay is a sustainable, natural material with a certain primitive character, which can be reinvented by the digital fabrication process, resulting in opposition of the artisan and the digital machine. Ceramic is higher in quality than plastic and depending on its viscosity it behaves differently when printed every time.

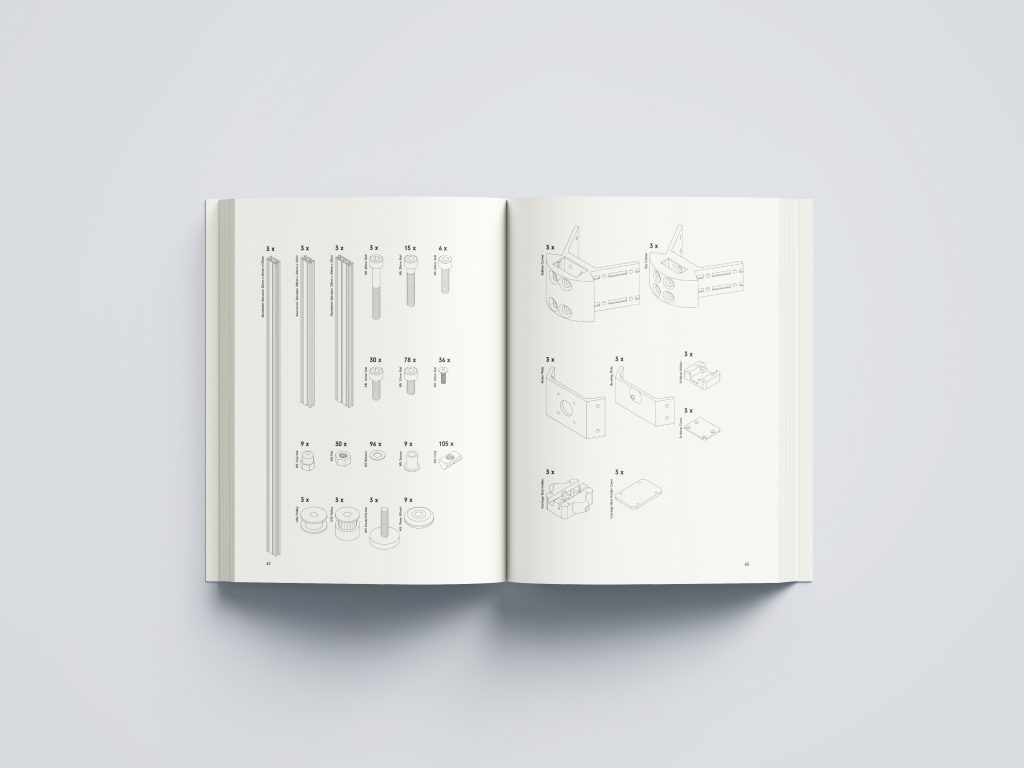

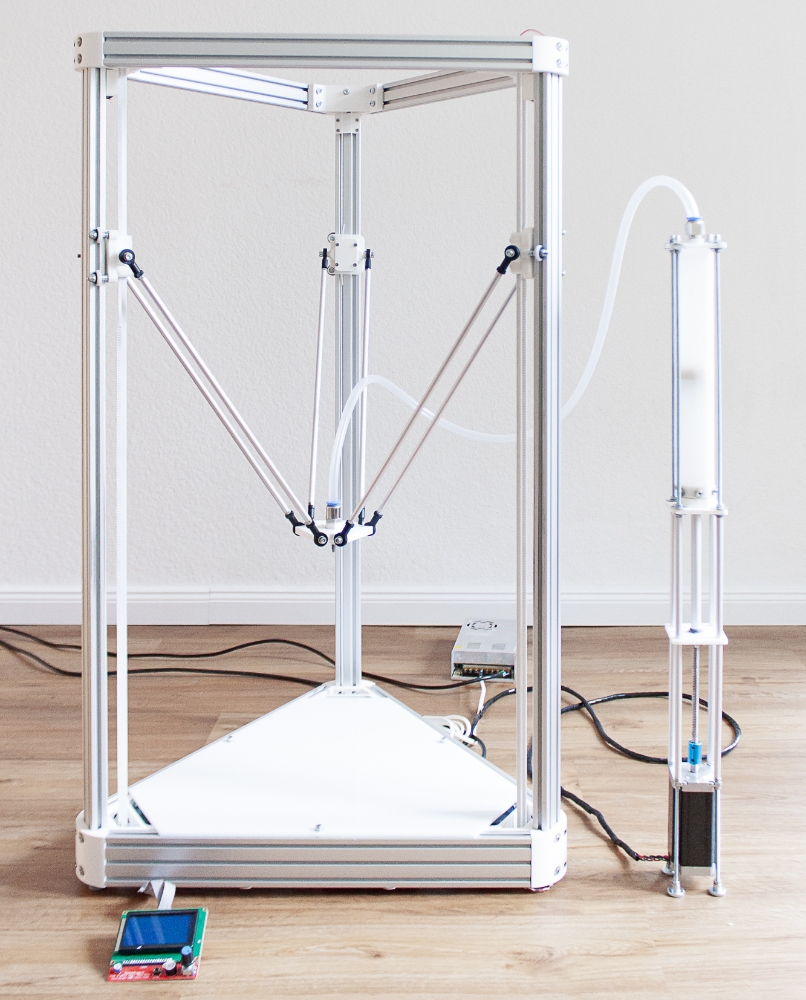

The core of this master thesis is the examination of the production process of ceramic goods in digital fabrication processes. Therefore I built a 3D-printer and produced three series of objects, which have been modified by working methods that are applied in craftsmanship.

In addition to the actual production of my workpieces, this work also focuses on the iterative development process of the machine itself and the associated examination of digital fabrication. Without any previous knowledge in the field of 3D printing or ceramics, I worked and researched on the technology and the materials to combine them eventually. In contrast to a classical craft, I did not have a master to assist me with this.

„Before the Industrial Revolution, most products were individually handmade by craftsmen who controlled the entire production process and had an extraordinary knowledge of all the materials and tools needed to create their items.“ Warnier, Verbruggen, Ehmann, Klanten – Printing Things p. 52

The classical form of knowledge transfer from the master to the apprentice is missing in this digitally influenced form of craftsmanship. My process of learning was very conscious and reminds much more of work in new digital professions, where there is often no tight compendium for training – one reads into a topic and tests the knowledge directly in practice.

Nevertheless, the masters exist of course. For example, Dries Verbruggen from unfold and Jonathan Keep, they make their knowledge available to everyone on the Internet. Thus I gained my knowledge about 3D printing of ceramics from forums, explanation videos, guidebooks as well as instructions and of course through trial and error. The Internet, therefore, takes a central position as a teaching medium and thus becomes my mentor.

„With manufacturing going digital, we can now see aspects of the pre-industrial craft economy merge with high-tech industrial production methods. […] One of the most important enablers and drivers of this shift is another digital invention which, in just 20 years, has managed to fundamentally change almost everything we do, from commerce to culture: the Internet.“ Warnier, Verbruggen, Ehmann, Klanten – Printing Things p. 52

The early potters developed slowly, it took almost 20000 years until the rotating potter‘s wheel was invented. Centuries passed before throwing clay became a routine. First, the activity of the hand had to become implicit knowledge.

According to Adam Smith, prehistoric craftsmen were probably not aware of the slow expansion of new artisanal technologies, as they took their methods for granted. John Ruskin questioned this theory and suggested that errors, imperfections and variations were most likely passed down from generation to generation through tradition.

In the Middle Ages eventually, there were neither architects nor blueprints, nevertheless, people managed to build structures like cathedrals throughout decades. Craftsmen, instead, passed on the basic idea of a building for generations, evolved it and implemented it collectively.

Even without the networking of the Internet, James Watt‘s steam engine prevailed in the 18th century. Instructions and blueprints for the construction of a steam engine were widely available in 1823. Watt had revealed all his secrets – the first open-source project, so to speak.

Thus, in the 19th century, a transition from personal knowledge to explicit knowledge emerged. In addition, the craftsman became less of the mediator and the enemy of the machine, given its perfection. Craftsmanship became an expression of individuality through variations, slight defects and irregularities in working with the hand.

„Alles Gescheite ist schon gedacht worden, man muss nur versuchen, es noch einmal zu denken.“ Goethe – Wilhelm Meisters Wanderjahre 41

Goethe, like all artists, was under pressure to claim originality for his work. Originality comes from the Greek word „poesis“. Plato and others use it in the sense of „something where there was nothing before“.

Originality also makes the difference between an artist and a craftsman. While the craftsman is pursuing an anonymous, collective practice, the artist is constantly striving to create something new, unique or outstanding. This is also evident from sociological differences, while the artist often acts as a single person, the craftsman works collectively.

The potter also became an artist, and around 800 BC ceramic products became increasingly more complex. They no longer served mere usefulness but were painted and decorated.

„The craftsman‘s workshop became the artist‘s studio, and the studio was also full of assistants and apprentices.“ Sennet – HandWerk p. 95

The studio lives from all the outstanding abilities of its master.

Thus the artist emerged from a community of craftsmen, because of his desire to express himself. The introverted artist is burdened with subjectivity, while the craftsman remains outwardly oriented towards society.

With my Master Thesis, I try to combine these extremes with each other and to apply them in such a way that they benefit each other. Allegedly the 3D printer is the perfect machine and digital fabrication always promises uniform results.

„The premise of 3D printing as a universally identical technique is somewhat mythical, both in terms of the physical constraints of mechanically imperfect

machines and the limitless opportunities for modifying open-source printers or experimenting with materials.“

Warnier, Verbruggen, Ehmann, Klanten – Printing Things p. 142

Maybe digital fabrication or digital craftsmanship is much more related to traditional craft. A repetitive process of designing, creating and improving is needed to further optimize the quality of the prints.

So I first have to master the craft before I can devote myself to art in order to avoid dilettantism.

„Wie kann man sich selbst kennen lernen? Durch Betrachten niemals, wohl aber durch Handeln“Goethe – Wilhelm Meisters Wanderjahre 41

Finally, the question for me is whether this process of digital fabrication makes me the craftsman mentioned above or whether my machine takes on this role and my function is completely new in terms of the craft.

Sennet raised this question and then discussed the social significance of machines. On the one hand, computer-aided design, or CAD for short, is an enormous simplification of work with an almost seductive potential. On the other hand, „it weakens the users‘ understanding of the object of their work“.

„Is [the machine] a blessed tool or an enemy, when it replaces the work of the human hand?“ Sennet – HandWerk p. 113

ITERATIONS

The Iterations series has its origin in traditional craftsmanship. The principle to repeat something again and again in order to get better at it and to learn and internalize the moves.

Although the same 3D model was printed, the results were never the same, even though the premise of 3D printing is to achieve universally identical objects. Potters never create perfect, identical workpieces, that is why I wanted to embrace the beauty of small irregularities and imperfections that makes each piece unique.

These irregularities are caused by slicer settings such as layer height, nozzle size and filament diameter. The material, whether the clay is soft or firm, contains chamotte or is very slippery. As well as the calibration of the printer itself.

METAMORPHOSIS

When the potter makes a ceramic vessel on the potter‘s wheel, he first pulls up the walls of a cylindrical body and then presses and pushes the material with his hands into the shape of a vase, bowl or cup. He proceeds slowly and gradually to change the clay so that it does not break.

Metamorphosis is a series of objects that change incrementally. The original form is always a cylinder, which is then changed step by step.

The slicer settings, printer configurations and the material remain the same in this series.

With this series, I want to test the potential of the machine and the material and develop a feeling for its possibilities. After each step, the next one is created, printed, improved and further created until the limits of what is possible are reached.

SYMBIOSIS

The Symbiosis series is inspired by Andrea Salvatori and WASP‘s „Ikebana Rock‘n‘Roll‘ a series of 3D printed vases with spherical inserts. Ikebana is the Japanese art of flower arrangements.

To test the limits of my machine, I tried to adapt Salvatori‘s approach. The goal is to disrupt the digital fabrication process or to create a symbiosis between the digital and my manual work. The machine will continue its process regardless of my actions, I want to encourage this behavior.

I formed round shapes out of clay by hand and colored them with black pigment, to further emphasize the contrast between the two components.

I prepared a cylindrical shape and started the print. After the first few layers, I placed the balls into the soft clay of the walls. I made sure to push them down far enough, so the nozzle would not hit them on the next layer and pull them out. After a certain height, the thin shells could no longer hold the heavy balls and tilted. Thus the upper layers are no longer firmly on top of each other but rather loose.

BETRIEBSSTÖRUNG

„Betriebsstörung“ (engl. malfunction) is a failure of the running process of a machine. The reason for this is a technically unexpected event that requires manual intervention to remedy the situation.

In addition to my intended object series, these „accidents“ have emerged. Their nature is due to incorrect settings, unsuitable or incorrectly prepared materials, technical defects or dropouts.